"OPPOsaurus WRX" (opposaurus)

"OPPOsaurus WRX" (opposaurus)

08/06/2015 at 09:37 ē Filed to: None

0

0

16

16

"OPPOsaurus WRX" (opposaurus)

"OPPOsaurus WRX" (opposaurus)

08/06/2015 at 09:37 ē Filed to: None |  0 0

|  16 16 |

Fix it your self they said. It will be fun they said. well why the blood sweat and tears when we could have had more beers? anyway this is where iím at. I got the hub pulled , which I can;t wait to put back on cuz i dunno how the F thats gunna happen but first this thing is stuck:

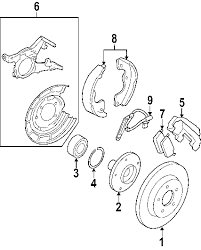

Its unbolted and all that, Iíve saturated it with PB blaster, and beat the hell out of it with a slammer (think hammer sized sledge hammer) How do I get it off? thats all that stands between me and my next unforeseen problem. I have the replacement. I probably could keep this one on but Iím a bit afraid to do that as I have been beating it with a hammer. The two things sticking out are where the brake pads slide and the two mounting bolt holes are right there. If I choose to reuse it, I have to completely disassemble the new e-brake instead of just installing it all as one piece

for refernce. the upper part of item #6 is whats stuck, the other piece is what needed to be replaced and has the entire e-brake assembly attached to it. (items 5,7,8, and 9)

SidewaysOnDirt still misses Bowie

> OPPOsaurus WRX

SidewaysOnDirt still misses Bowie

> OPPOsaurus WRX

08/06/2015 at 09:38 |

|

Sounds like you need a bigger hammer.

OPPOsaurus WRX

> SidewaysOnDirt still misses Bowie

OPPOsaurus WRX

> SidewaysOnDirt still misses Bowie

08/06/2015 at 09:42 |

|

is that all there really is too it? I beat the thing for half an hour last night without any progress. Can I use a torch to heat it up or is there too much sensitive stuff around there?

Brickman

> OPPOsaurus WRX

Brickman

> OPPOsaurus WRX

08/06/2015 at 09:48 |

|

Itís rusted on for so many years. Soak it around the edges, tap the areas (helps the pb blaster get in between the metal), then get a deadblow hammer and hit it in alternating sides. Also try using a pry bar, but careful not to damage any important stuff like that hose or cable.

SidewaysOnDirt still misses Bowie

> OPPOsaurus WRX

SidewaysOnDirt still misses Bowie

> OPPOsaurus WRX

08/06/2015 at 09:51 |

|

Yeah, it really should be it unless youíre missing something. These things fit tight. The bearing usually has to be pressed in, and thatís probably whatís holding it in place. As far as using a torch, I donít really see a problem depending on where the CV joints are for the axle (is that an axle Iím seeing, or just a round lower control arm?). If itís just FWD and thereís no axle, I wouldnít be worried about it but you might want to get a second oppopinion. FWIW,

Ford recommend using a wheel puller tool

.

Eberle-Hills-Cop

> OPPOsaurus WRX

Eberle-Hills-Cop

> OPPOsaurus WRX

08/06/2015 at 09:51 |

|

Perhaps try Mjolnir.

OPPOsaurus WRX

> SidewaysOnDirt still misses Bowie

OPPOsaurus WRX

> SidewaysOnDirt still misses Bowie

08/06/2015 at 09:55 |

|

its AWD, the hubs pulled and the bearings do not need to come out. the part actually slides over the bearing housing part

OPPOsaurus WRX

> Eberle-Hills-Cop

OPPOsaurus WRX

> Eberle-Hills-Cop

08/06/2015 at 09:56 |

|

iíd like to leave the rest of the parts attached to the car.

SidewaysOnDirt still misses Bowie

> OPPOsaurus WRX

SidewaysOnDirt still misses Bowie

> OPPOsaurus WRX

08/06/2015 at 09:57 |

|

Hmm... weird. I donít know then. It shouldnít be putting up this much of a fight.

OPPOsaurus WRX

> SidewaysOnDirt still misses Bowie

OPPOsaurus WRX

> SidewaysOnDirt still misses Bowie

08/06/2015 at 10:03 |

|

everything seems to have more rust that you would expect

Eberle-Hills-Cop

> OPPOsaurus WRX

Eberle-Hills-Cop

> OPPOsaurus WRX

08/06/2015 at 10:16 |

|

Valid concern.

Rico

> OPPOsaurus WRX

Rico

> OPPOsaurus WRX

08/06/2015 at 10:36 |

|

See I get the appeal of DIY but seeing something like this Iíd rather hand somebody a hundy and say bring it back to me fixed while I go kick back and relax.

Good luck and Godspeed!

OPPOsaurus WRX

> Rico

OPPOsaurus WRX

> Rico

08/06/2015 at 10:43 |

|

my knuckles 100% agree with you.

Rico

> OPPOsaurus WRX

Rico

> OPPOsaurus WRX

08/06/2015 at 10:47 |

|

Are they bloody? No pain no gain!

uofime-2

> OPPOsaurus WRX

uofime-2

> OPPOsaurus WRX

08/06/2015 at 11:13 |

|

Is the suspension moving when you hit it with the hammer?

You might try supporting the lower ball joint with a jack when you whack it.

Beat it in both directions.

Beat it in a star pattern like you use of for lug nuts.

Consider investing in a dead blow hammer (the orange ones filled with shot are my favorite), mini-sledges are scary when they rebound.

This was probably unhelpful, good luck

OPPOsaurus WRX

> uofime-2

OPPOsaurus WRX

> uofime-2

08/06/2015 at 11:28 |

|

there is a specific jacking point with a scissor jack under it just outside the picture to the right. the suspension does move when I hit it.

cazzyodo

> OPPOsaurus WRX

cazzyodo

> OPPOsaurus WRX

08/06/2015 at 11:28 |

|

Fuckiní Northeast winters.